BioForm

Rethinking how we design and develop biomaterials, considering their full range of properties, not just as an alternative or replacement for non-renewables.

Materials Design

Digital Fabrication

Biopolymers

Duration

5 months

Collaborators

Chia-Jung Kuo

Motivation

Our driving question was how could we push the boundaries of designing with well-known biomaterials, beyond the expected forms of a flexible film, or rigid molded block.

We believed that by designing outside of the expectation of hitting the specs for non-renewable plastics, we could explore this material to its full potential, and leverage its inherent affordances to develop unique properties.

Proposition

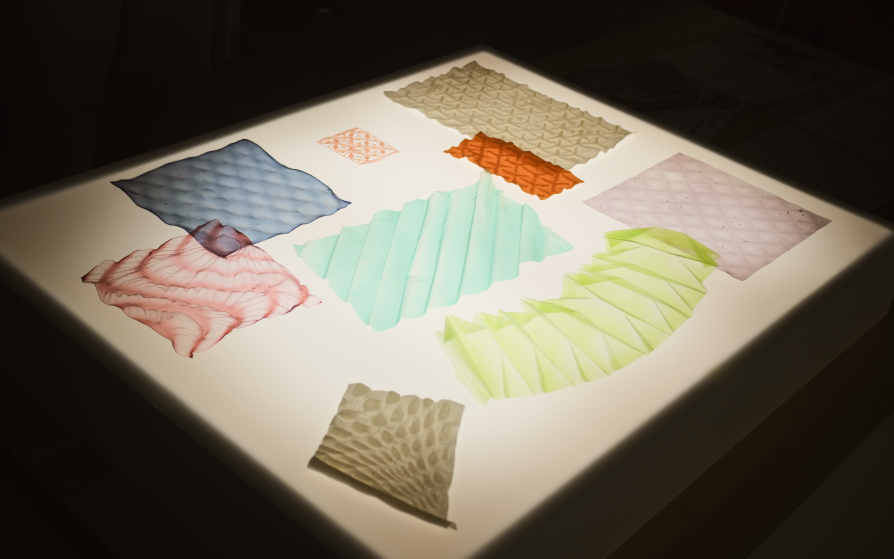

We focused on a bioplastic made from red algae, due to its simplicity in ingredients- agarose, glycerine, and water- and the potential to fabricate in many ways due to agarose's unique gelling properties.

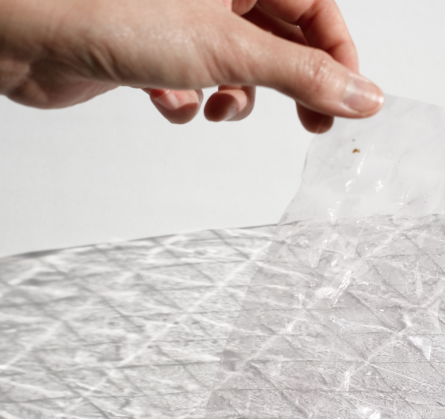

Through a long series of testing several different design possibilities, we highlighted the properties that were unique to this material, including shrinkage, gel state, heat and moisture sensitivity, and focused on repeatability and scaling of the selected affordances. We were able to achieve materials beyond the swatch scale, with the largest pieces measuring 3 ft x 8 ft.

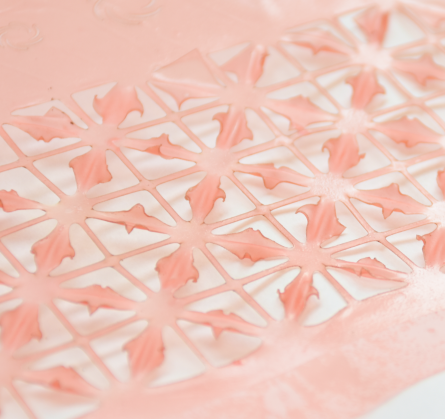

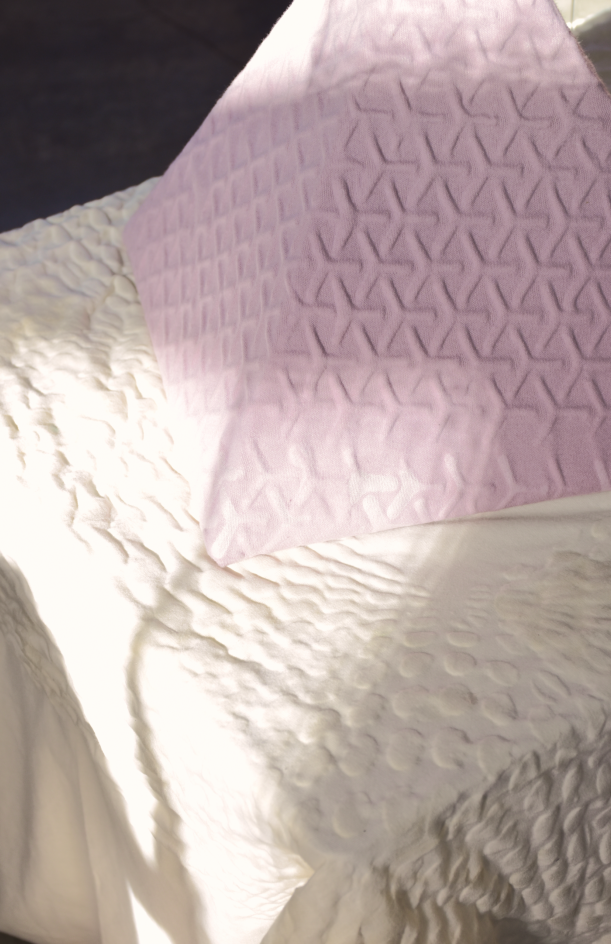

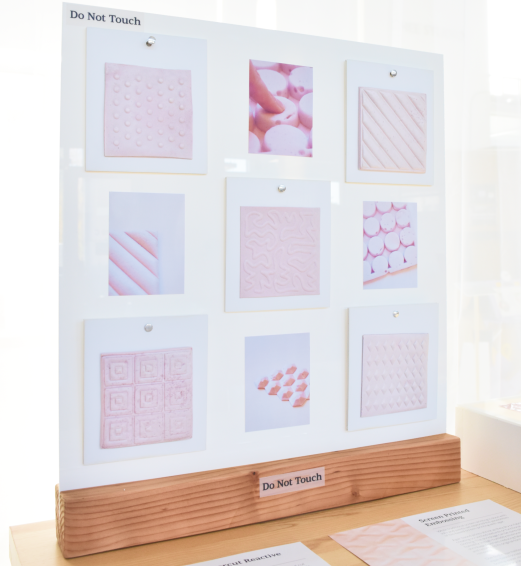

Reactive Patterning: Laser cut patterns on the bioplastic sheet results in controlled shrinkage when heated >80 C to create surface porosity control mechanisms, low energy sensing systems, and mesmerizing patterns. In a localized high-humidity environment, reversible actuation occurs along the cut lines.

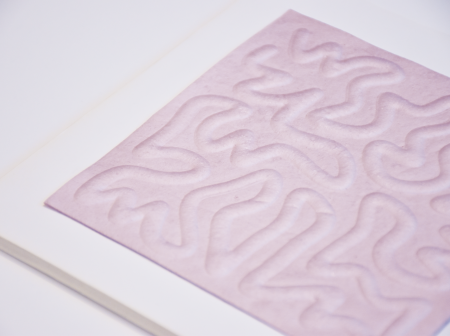

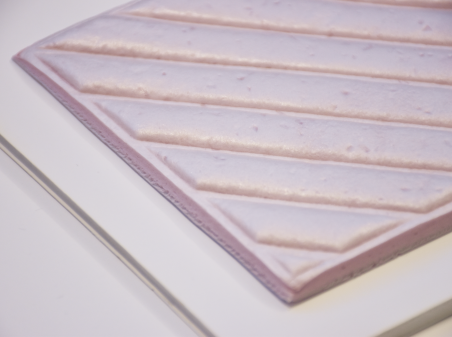

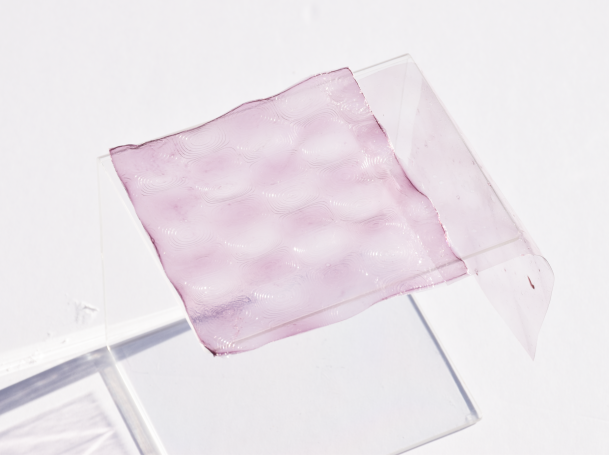

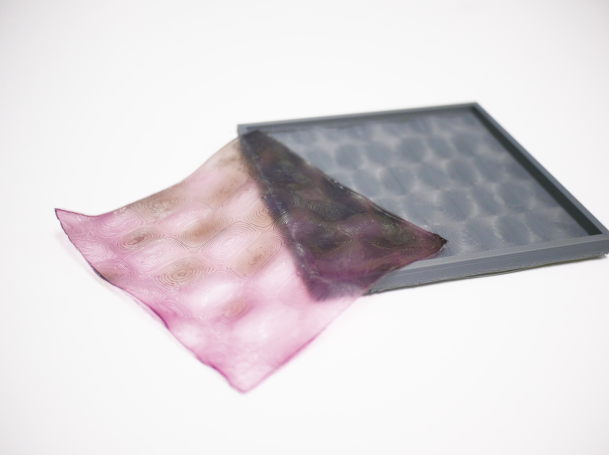

Tunable Foam: Molded foam structures created by the addition of an expanding agent. Compressibility and reversibility of compression can be fine tuned based on formulation. Creates lightweight 3D structures that are buoyant, spongy, and sound absorbent. Can last in aquatic environments for 5-7 days before safe degradation.

Contribution

I led the materials development, testing, and characterization for this project, leveraging my past experience in formulating with biopolymers such as alginate, agarose, polysaccharides, gelatin, and chitosan. We were able to fine tune our recipe to allow us to develop bioplastics with maximal strength and minimal shrinkage or warping. In addition Chia-Jung and I collaborating on developing various aesthetic forms and patterns to depict with each affordance, highlighting its visual customizability for designers.

Scanning Electron Microscopy