Carbon x Dentsply

Developing and validating a series of denture resins that can reduce the labor intensive process of denture manufacturing, and meet the highest impact criteria.

Materials Engineering

Project Management

Additive Manufacturing

Validation and Quality Testing

Duration

2.5 years

Recognition

Best Denture Resins iDD’s Dental 3D Printer Awards 2024

Collaborators

Greg Robbins

Sneha Kelkar

Md Abu Hasan

Kyle Kloster

& many more

Motivation

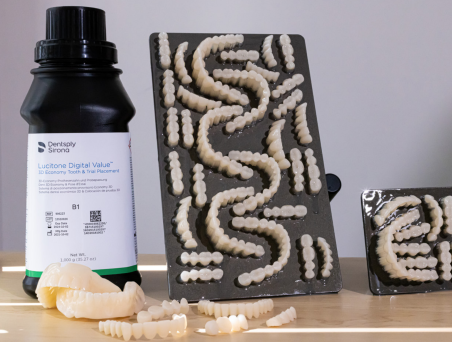

The goal was to develop the first high impact, premium 3D printable Denture material - Lucitone Digital Print with Portrait IPN teeth, Lucitone Digital IPN Teeth, & Lucitone Digital Value Teeth.

Denture manufacturing is traditionally a very labor intensive process, using subtractive manufacturing, and requiring a skilled technician with years of training. Existing 3D printable Denture resins were used for lower-end dentures, and did not have as high quality finish as the traditional process. With advancements in digital scanning technology and additive manufacturing, we can cut down on material waste, remove niche skill requirements, and reduce labor needed to produce high quality dentures.

Contribution

I was the technical project lead for Carbon.

I led all collaborative client meetings and technical efforts with Dentsply Sirona, and was the point person for troubleshooting and cross functional efforts across materials, hardware, software for this project.

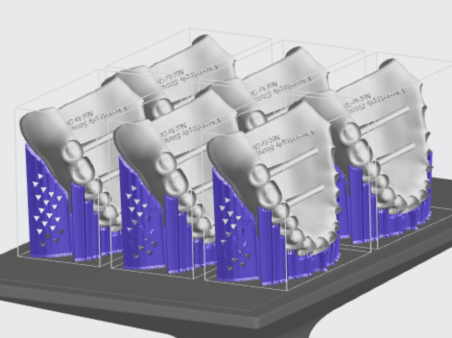

I developed and validated printing and post-processing workflows on the Carbon platform for Lucitone Digital Print and Lucitone Digital Try-in/Value Tooth resins, and critically evaluated printed parts including mechanical properties and accuracy testing. In addition, I helped create and validate a new software automation tool for denture production that reduces pre-prep time by approximately 50% (automatically nests, orients and supports denture bases).

Characterization and Testing

Dentures must go through rigorous testing for mechanical, accuracy and biocompatibility properties to pass FDA standards.

Mechanical Properties must pass ISO standards in Flexural Strength, Modulus, Fracture Toughness & Work of Fracture. Denture accuracy is tested by CT Scanning and evaluation for teeth and intaglio surface of denture base. Orientation and support settings are optimized for maximum accuracy. Variability in properties must be tested across resin lots, denture base and teeth shades, printer, software, and hardware variations.

Software Automation Tool

The Denture Automation Tool streamlines the workflow for dental labs.

This tool provides users the option in the Carbon UI to upload denture base and try-in files, and automatically orient, support and arrange parts on the platform. I assisted software engineers by defining the logic required to identify denture type (Uppers vs Lowers, Try-ins with teeth), and determine the appropriate supports to be added automatically. I tested a large database of over 60 parts to ensure the tool works appropriately on >85% of cases, and parts print within specs.

Sources

https://www.youtube.com/watch?v=zo7WKk_XTNM

https://www.youtube.com/watch?v=zkeCzGMwOUg

https://www.carbon3d.com/software-release-notes/

https://www.carbon3d.com/materials/lucitone-digital-print/