EcoSeal

Combatting waste in the produce shipping industry by working alongside one of the largest cardboard manufacturers in North America to develop alternative solutions for wax coated boxes.

Innovation Consulting

Material Coatings

Packaging Design

Duration

5 months

Recognition

Finalist at SCET Collider Cup 2023

Collaborators

Allie McAndrews

Mingzhou Gu

Hyejin Byun

Fernando Bustamante

Motivation

Wax coated boxes are used for high-protection produce such as broccoli and asparagus that need to be shipped with ice. Wax ensures the boxes are and intact, but cannot be recycled and ends up in landfill.

Obvious solutions like plant-based waxes have not been feasible due to the large quantities required to match performance, and the inability of waste facilities to distinguish between different types of wax coatings.

This client has the goal of 100% recyclable boxes by 2030, and wax-coated boxes account for 1% of their business, which is over 8 million boxes per year going to landfill.

Video Credit: @tony98discovery, youtube

Key Metrics

There were 3 key parameters to prioritize in looking for a replacement to wax coatings. These were:

- Hydrophobicity: To withstand direct contact with ice during shipping.

- Repulpability: To allow for recycling of fibers up to 7 times.

- Structural Integrity: So boxes can be stacked,

Additional metrics included ensuring the solution was plastic-free, can be produced efficiently, and had a relatively low lead time for R&D.

"Finding a solution that beats the cost and usability of plastic is difficult"

- CSA Farm

"....recycling isn't a very good option. The waste disposal systems need a lot of work."

- Waste Management Expert

"We can leverage ice and produce to provide strength to the boxes"

- Stakeholder

User Research and Insights

We interviewed over ten farmers, CSA's, and experts in materials, waste disposal, and packaging, as well as stakeholders from our client company.

While many had uncertainties that this problem could be eliminated, we also had a lot of positive feedback and response.

Research Directions

We approached this problem through 3 research directions, after synthesizing interview insights, and doing desk research from research journals and competitive analysis.

Material Coatings

Looked at research in parallel industries to identify recyclable coatings. Our two main solutions here are:

Kapok Fibers: waterproof natural fibers from a tropical tree.

Chitosan: second most abundant biopolymer from crustacean shells.

Modular Design

Using a modular approach to create a lined box that can be easily separated before disposal.

Existing Solutions

We found an existing solution on the market, Recool by Igloo, a molded fiber cooler that is water resistant and 100% recyclable (made from recycled paper and alkyle ketene dimer, AKD).

Prototyping

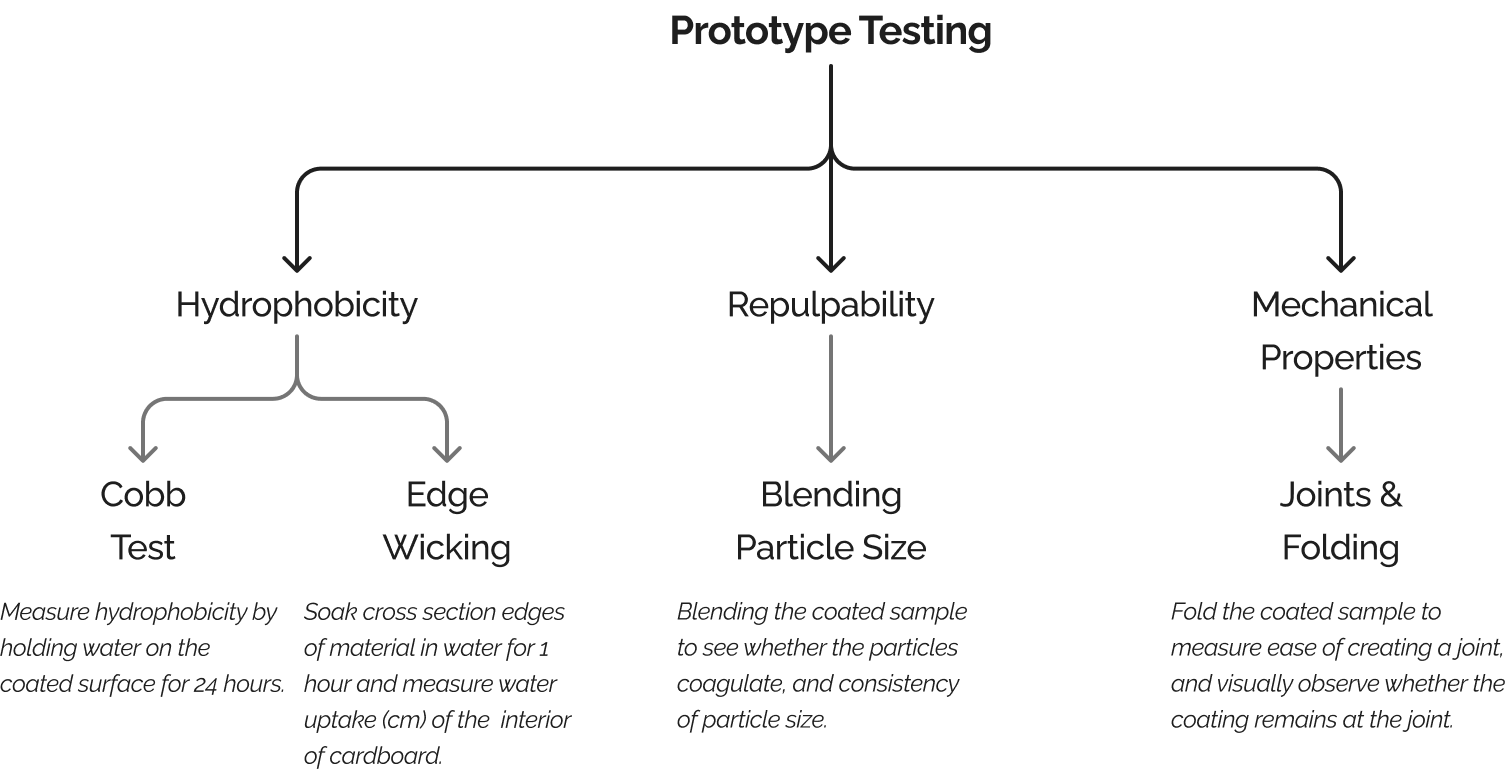

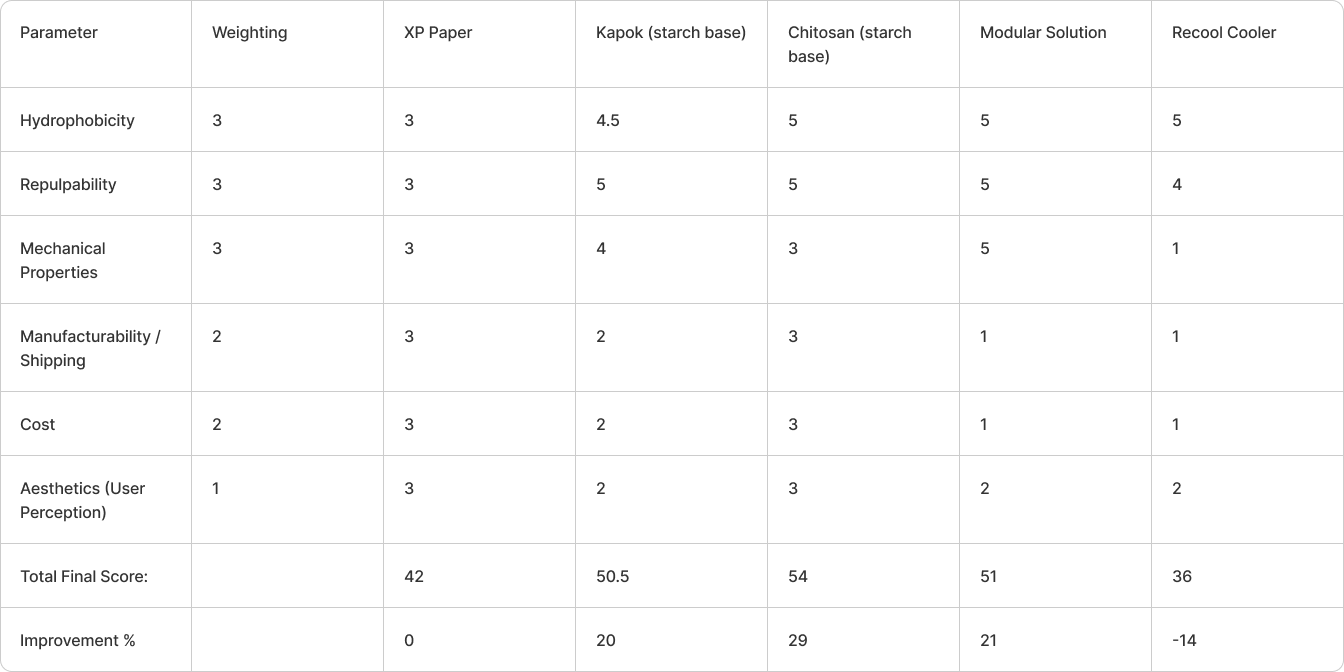

We collaborated with the client to create a series of tests that allow us to evaluate and score the performance of the samples. We tested 4 samples: chitosan coated, kapok fiber coated, dual material (aluminum and paper, purchased) and the recool cooler (purchased).

The tests as well as their descriptions are listed below. The results were scored quantitatively where possible, and qualitatively otherwise, in the table shown below. The most important properties were weighted more heavily than other factors that the client deprioritized.

This work provided the client with a starting place to decide where to spend their R&D time and efforts.

Theory of Change & Impact

I learnt a lot about the agricultural sector through this project, and more than I ever know about the waste disposal system in our country. It made me reflect on what the future of agriculture will look like, especially in a more localized, community grown, and urban environment, which may entirely eliminate the shipping issues of this client.

Material Coatings

up to

1.8k tons

of wax boxes diverted from landfills per year

Existing Manufacturing and Recycling Facilities

will need minimal changes to accelerate the transition

Modular Design

up to

0.8k tons

of wax boxes diverted from landfills per year

up to

150 tons

extra waste from consumers not separating linings appropriately

Existing Solutions

up to

1.8k tons

of wax boxes diverted from landfills per year

Requires Strong Reusability Habits

from consumers as well as supporting policy

Localized Markets:

Stop Shipping High Protection Produce

up to

3.8k tons

of wax boxes diverted from landfills per year

Zero Transportation Emissions

and creates new business and partnership opportunities

Sources

https://www.atlaspackaging.co.uk/case-studies/vegetable-packaging-boxes

https://impermeamaterials.com/blogs/news/the-importance-of-repulpability-in-packaging-coatings-a-look-at-impermea-s-sustainable-solutions

https://www.shutterstock.com/hi/image-photo/lots-broccoli-on-ice-trays-supermarkets-2172280257

https://www.bynori.eu/fiber/virgin-kapok-1kg

https://www.alibaba.com/product-detail/Dry-Shrimp-Shells-for-Make-Chitin_50035544479.html

https://wfpgroup.com/product/thermal-boxes-foil/

https://www.amazon.com/Igloo-Recool-Cooler-qt-Tan/dp/B07W5QW7ZV

https://architizer.com/blog/practice/details/growth-environment-architects-modernizing-farming-smart-agriculture/